|

|

|

| |

Electronic

Components & Chemical Ceramics |

|

|

|

|

|

|

|

www.aumtechnocera.com |

|

| Special |

|

| Electronic |

| Electronic

Ceramics Components |

|

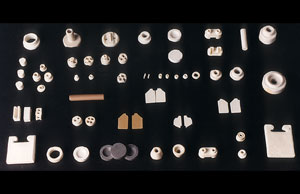

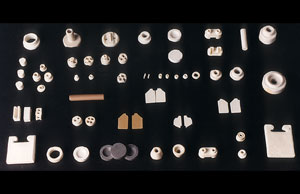

We

manufacture electronic ceramics in steatite, cordarite,

high alumina and the product confirms to DIN / IEC

standard. The productions are made tailor-made that can

be must produce or individually produced in units only.

The enduse of the products are electronics, power

engineering, textiles and yarn manufacturers.

|

|

|

|

|

|

|

| Electronic

Ceramic | Electro

Porcelain

| HRC Fuses

|

Liners & Wear Resistance Parts

|

Tubes & Pipes

|

Chemical Ceramics

|

| TECHNICAL

& STRUCTURAL CERAMICS

| TOP | |

|

www.aumtechnocera.com |

|

|

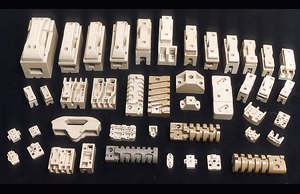

Electro Porcelain |

|

Composition |

Products |

Application |

|

wWhite glazed

& unglazed in

nature

wPorosity

less than 0.25%

wMechanically

Strong

wHigh Electrical

& Insulator

|

|

|

wLT &

HT insulators like coil

formes, Blocks,

Bush &

otherShapes.

|

|

|

wSwitchgear manufacturing

wState

Electricity Boards

wIndian

Railways

wPower

Station

wElectrical Applicances

|

|

|

|

|

|

Aum

Techno Ceramic offers wide range of high quality electro

porcelain from 5 Amps to 500 Amps.

The products are manufactured under stringent

quality control at every stage of production from raw

material selection to the finished products, the quality

confirms to BIS, DIN, BSS or IEC.

|

|

|

|

|

|

|

|

| Electronic

Ceramic | Electro

Porcelain

|

HRC Fuses

|

Liners & Wear Resistance Parts

| Tubes

& Pipes |

Chemical

Ceramics

|

| TECHNICAL

& STRUCTURAL CERAMICS

| TOP |

|

|

www.aumtechnocera.com |

|

|

HRC

round and Square fuses |

| Composition |

Products |

Application |

wZircon Cordirite (C

520)

wSteatite Bodies (C

221)

as per BS/DIN Standards

wThermal Shock

Resistance

wVery high

Bursting Strength. |

|

wHRC round

Barrels

wRectangular or Square Fuses. |

|

wVarious Switchgear Industries. |

|

|

|

|

|

Aum Techno Ceramic manufacturers full range of HRC Fuse

bodies both round and wickman time in zircon cordarite,

high alumina and or steatite 221.

The products have exceptionally high mechanical

strength and very high thermal shock resistance. Tubes and

star cores for high voltage applications are made from

3.3KV to 33KV applications. |

|

|

|

|

| Electronic

Ceramic | Electro

Porcelain

|

HRC Fuses

|

Liners & Wear Resistance Parts

| Tubes

& Pipes

|

Chemical

Ceramics

|

| TECHNICAL

& STRUCTURAL CERAMICS

| TOP | |

|

www.aumtechnocera.com |

|

| linn |

|

|

|

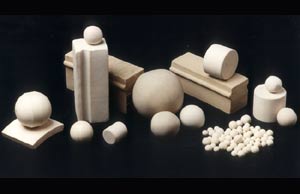

CERAMIC

LINERS

& MEDIA FOR GRINDING / DISPERSION. |

|

Aum

Techno Ceramic manufactures ceramic linners

for ball mills in different qualities and

sizes. Normal sizes are: 150X150X50,

150X50X60, 150X75X50 in both flat and tapper.

The mill linners are manufactured in hard

porcelain or high alumina as per customerís

requirement. |

|

|

| |

|

Electronic

Ceramic | Electro

Porcelain

|

HRC Fuses

|

Liners & Wear Resistance Parts

| Tubes

& Pipes

|

Chemical

Ceramics

|

| TECHNICAL

& STRUCTURAL CERAMICS

| TOP | |

|

www.aumtechnocera.com |

|

|

|

| tubes |

|

|

|

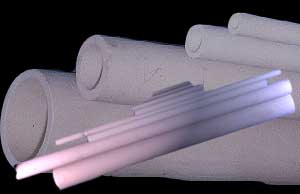

TUBES

FOR FURNACES |

|

information required |

|

|

|

|

Electronic

Ceramic | Electro

Porcelain

|

HRC Fuses

|

Liners & Wear Resistance Parts

| Tubes

& Pipes

|

Chemical

Ceramics

|

| TECHNICAL

& STRUCTURAL CERAMICS

| TOP | |

|

www.aumtechnocera.com |

|

|

|

CHEMICAL CERAMICS |

|

|

| Composition |

Products |

Application |

wWhite in

color

w

Porosity less than 0.25%

wGood

Mechanical Strength

w

Acid & Alkali proof. |

|

wTower packing items like, Pall rings, Rasching

Rings and Saddles of various sizes and shapes. Crucible of different sizes

and shapes. |

|

wFractional Distillation of Chemicals and Gases,

Refineries, Petrochemicals and Fertilizers Chemical Industries. Analytical

and Metrological Laboratories, R&D of Steel Plants and Foundry. |

|

|

|

|

|

|

|

| Electronic

Ceramic

| Electro

Porcelain

|

HRC Fuses

|

Liners & Wear Resistance Parts

| Tubes

& Pipes

|

Chemical

Ceramics

|

| TECHNICAL

& STRUCTURAL CERAMICS

|

TOP | |

|

www.aumtechnocera.com |